Hydrotechnik were tasked with the design and manufacture of a test rig that would replicate the loading conditions of a dynamic seal to simulate its real-world application. This allowed the client to gain crucial insight and tangible data relating to the failure points of the seal, without having to deploy the literal device the seal is used in, which wouldn't be cost-efficient.

Unlike most of our projects which are commissioned to customers for testing on their site, we conducted all the seal testing in house alongside the client. They utilised our flexibility and reliability to get their project over the line with the knowledge and assurance that their seals were fit for purpose.

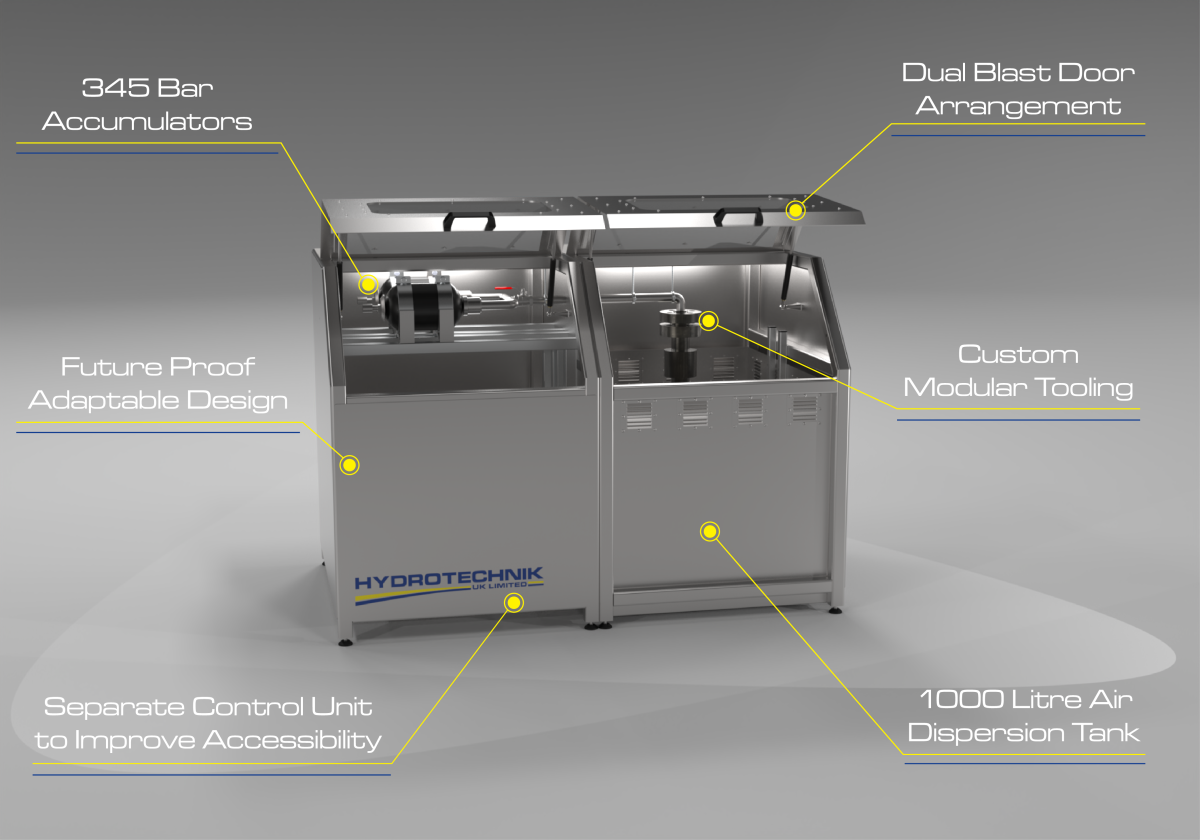

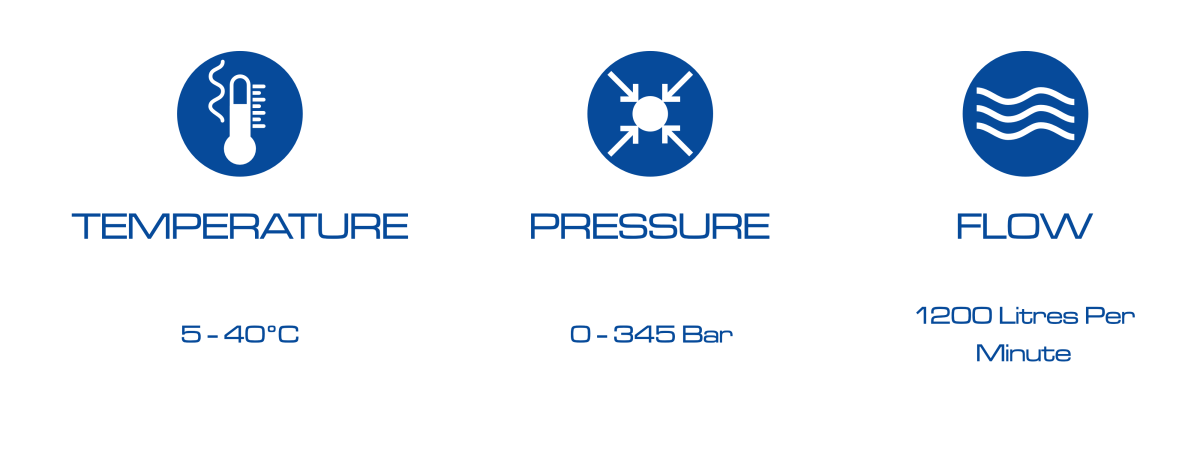

The rig produced its own compressed air and stored it in two accumulators each holding 200 bar. A total of 800 litres of air was rapidly released from the accumulators within 10 milliseconds, through custom modular tooling that mimicked the real-world apparatus. The pass criteria for the test were for the seal to remain in its position without any change in shape or dislodging from its seating groove once the pressurised air was exerted behind it. Due to the high pressures used during the tests the control system for the rig was designed as a separate wall mounted unit, with it's own 5060 data logger. This ensured the user was kept at a safe distance whenever a test was underway.

Contact Us

- Freephone0800 068 4134

- Phone+44(0)1159 003550

- Emailsales@hydrotechnik.co.uk

Test rigs