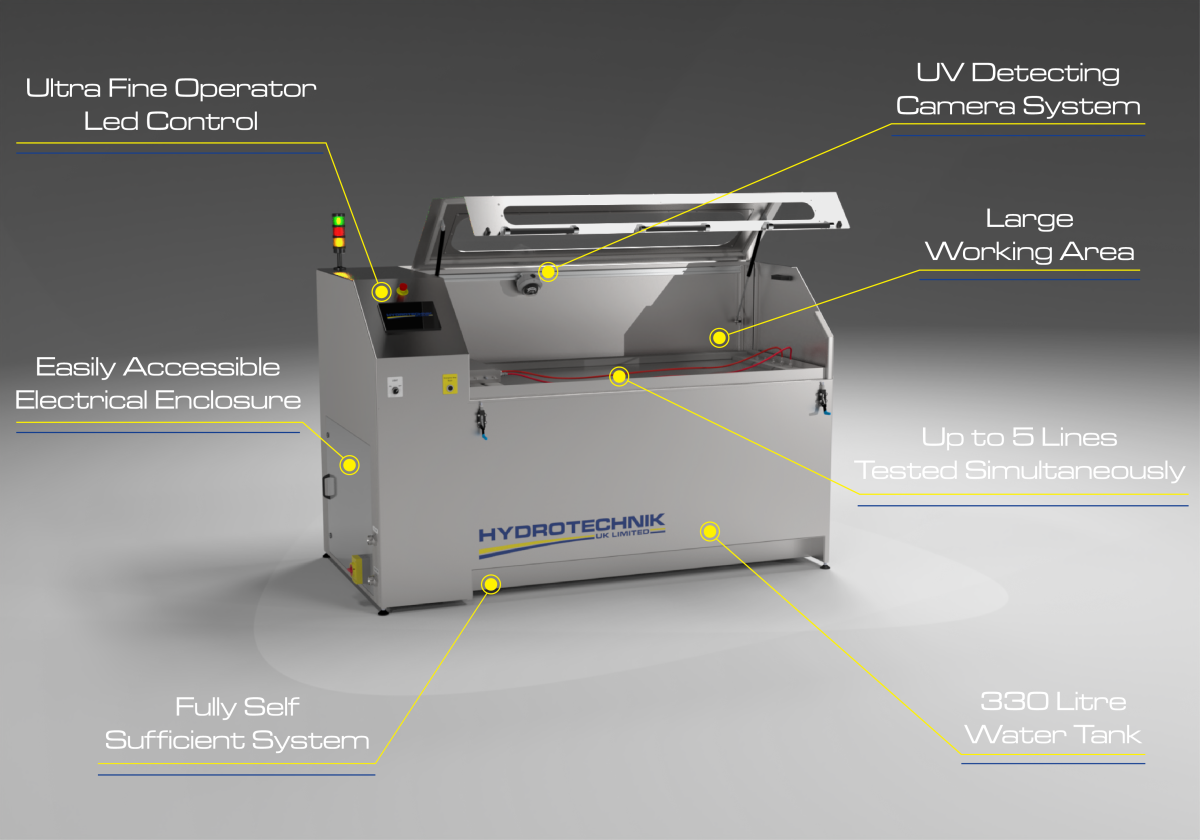

Hydrotechnik were approached by a renowned component supplier, that provide fluid transfer systems to the automotive and motor racing markets, to provide a test solution for a range of hose assemblies. The testing system needed to be capable of hydrostatic testing on five different components simultaneously, potentially at different pressure targets, with an operating pressure range in the components of 0.7psi to 10,000psi. The system previously used by the company was a completely manual rig, which had no means to accurately control a test at 0.7psi and no real-time data logging, or certificate production.

The project was targeted at delivering a system that would be ‘push and play’ for the customer, meaning that once setup by the operator the system would be capable of conducting the test and providing a conclusion automatically.The customer now has a complete self-sufficient system that can perform the required test with no intervention during the test cycle. The unit produces an automated test certificate when the test is complete, clearly showing the end user whether the test piece has passed or failed and what the real time pressure curve looked like in graph format.

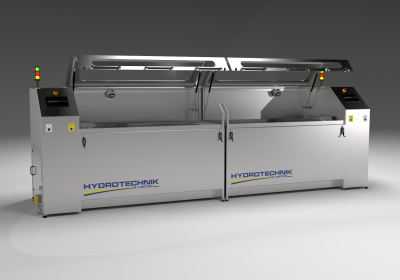

Hydrotechnik also supplied the client with a sister unit that is an identical, but mirrored, version of the original. Each rig can be used individually, but when a larger component needs to be tested they have the unique ability to be used side by side in unison, at which point one of the rigs becomes the master unit and the test is controlled through its HMI.

Contact Us

- Freephone0800 068 4134

- Phone+44(0)1159 003550

- Emailsales@hydrotechnik.co.uk

Test rigs