A Test rig is a piece of machinery that is primarily used to test and assess the capability and performance of components for industrial use. The term test rig is sometimes also referred to as test bay, test bench, pressure test facility and testing station but they all refer to equipment that carry out component testing.

Test rigs are deployed in a wide range of industries from hydraulic to aerospace and are capable of testing an unlimited amount of parameters in a wide variety of testing methods. From burst testing to cyclical testing, manual testing to brake testing. No matter what type of testing is required Hydrotechnik UK can deliver the right test rig solution for you.

Having supplied testing rigs for a large and varied range of customers over a multitude of industries over the past twenty five years, our expert team are best placed to help you every step of the way from consultation to user training.

Below you will find just a few of the different type of test rigs we offer and a range of in-depth case studies.

Find out the answers to common test rig questions.

Hydrostatic, Fluid Power and Pressure Test Rigs

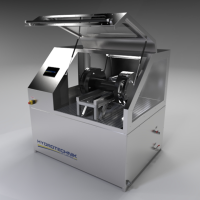

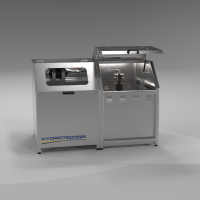

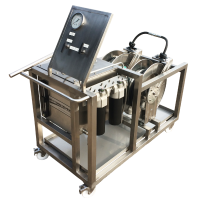

Hydrotechnik UK have extensive experience in the design, development, manufacture and commissioning of fluid power test rigs for end of production sign off or component testing. Our test rigs are used in demanding and ‘mission critical’ applications including defence, manufacturing quality control, plant maintenance and Research and Development. Users of Hydrotechnik test rigs rigorously test pumps, hydraulic hoses, moulded coolant hoses, pipes, manifolds, tanks, accumulators, valves and many other components to ensure they are fit for that purpose.

Component and hydrostatic test rigs

We specialise in the design and build of purpose built test rigs for hydrostatic pressure or flow testing of components. Logging of high speed pressure spikes and burst criteria as well as flow rate tests and integrity testing are our speciality. Our deep understanding of pressure, temperature, flow, RPM, Vibration, Cleanliness & Torque test and logging gives us a great insight when it comes to designing cost effective solutions for testing & proving of components and systems. Our systems can easily record at the rate of 10,000 readings per second.

We can test multi channels simultaneously and provide archiving software and graphical reports. The software can be written to give simple operator led control of the test procedures and simple green/red pass or fail warnings. The operator can add testing notes, serial numbers etc. for accurate traceability.

Our engineers take a full brief from the client and tailor make a test rig and software that ensures the finished product is efficient to use and enhances productivity.

Recent component and hydrostatic test projects include:

- Water pressure test rig for testing & datalogging of valve leakage & pressure integrity up to 15,000psi

- Test rig unit for testing of millibar differential pressure across large re-cleanable filter elements

- Test & Data logging rig for proof pressurising & deformation measurement of different hose assemblies

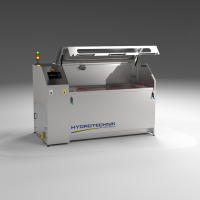

End of production test & data logging test rigs

Hydrotechnik UK can build bespoke data acquisition and testing units for measurement of flow, pressure, temperature, rpm, torque, noise, vibration, oil cleanliness & much more. From just a few channels up to 64 can be catered for. Our in-house team can produce operator led touch screen controls to ensure consistency of tests as well as storing operator notes, serial numbers and test data for archiving/customer sign off.

All our software is written to customer specifications for specific step by testing, monitoring & datalogging. Local or server data management for archiving & reporting of all recorded data.

Recent end of production test rig projects include:

- Permanent monitoring & datalogging of 16 pressure channels in a packaging factory

- End of line testing of flow, pressure & temperature on construction/earth moving machines

- Performance testing of flow, pressure temperature, rpm, torques & oil cleanliness at an OEM gear and radial piston pump manufacturer

- End of production test and sign off at a major Road sweeper company.

Hydrotechnik’s turnkey service includes everything from taking the initial brief through to delivery to site, installation, commissioning and staff training. All Hydrotechnik rigs are designed, using a sophisticated 3D CAD system, and manufactured under ISO 9001 procedures to the highest engineering standards. Our test rigs have been specified by global companies working in the hydraulic, pneumatic, plant engineering and automotive sectors.

Product Range

Contact Us

- Freephone0800 068 4134

- Phone+44(0)1159 003550

- Emailsales@hydrotechnik.co.uk

Test rigs