Designed and built in Nottingham, our bespoke pressure and flow testing rigs are proving popular. Our latest testing rig leak tests heat exchangers, which are fitted onto military plane wings.

The military organisation sent across the following specification:

• Manually operated test pump with hand operated pressure control

• Flow control valve, providing 25 cc/stroke

• Capable of pressure testing 100psi

• 50 litre tank to store oil

• Oil to be filtered down to 5 microns before returning to tank

Design

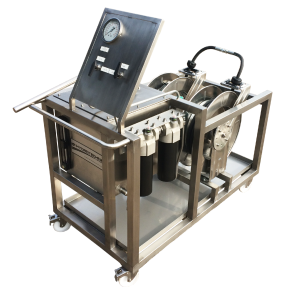

The test rig was designed at our Nottingham office with safety and functionality for the operator in mind. Sturdy but mobile, the manually operated test bench has all the key instrumentation on the front facing panel, enabling the user to quickly see the testing parameters.

Build

Built from 316 stainless, the rig is built to withstand harsh environments. The 50-litre tank housed onto a test bed frame with 4 wheels provides stability and mobility, as and when required. The testing rig has been fitted with two filters to provide clean oil to the heat exchangers whilst they are tested.

Instrumentation

This test rig has been fitted with a UKAS calibrated pressure gauge, providing accurate and reliable real time pressure readings. A flow control valve providing 25 cc/stroke ensures the flow of oil is controlled throughout testing, with the aid of 5 metre hoses. High quality Schroeder filters are fitted with easy-to-see visual blockage indicators.

How does it work?

This test rig has two key roles: the ability to flush any contamination in the heat exchanger and indicate whether it has any potential leaks. The manual solution gives the customer the flexibility to test at any point, in any location.

If you are looking for a hydraulic or hydrostatic test rig to carry out pressure, leak or burst tests on test pieces, then call us on 0115 9003550. If you prefer to email, please use sales@hydrotechnik.co.uk.

Contact Us

- Freephone0800 068 4134

- Phone+44(0)1159 003550

- Emailsales@hydrotechnik.co.uk

Test rigs